Industry Newsroom

SAP Unveils AI-Driven Supply-Chain Innovations to Transform Manufacturing

Written by: CDO Magazine Bureau

Updated 11:58 AM UTC, Mon April 22, 2024

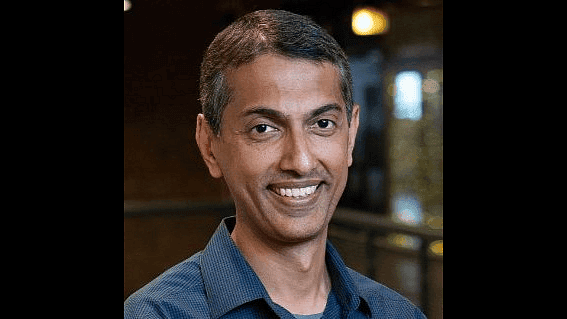

Muhammad Alam, member of the Executive Board of SAP SE, SAP Product Engineering

(EMEA) SAP SE today announced AI advancements in its supply chain solutions that will unleash a transformative wave of productivity, efficiency and precision in manufacturing. AI-driven insights from real-time data will help companies use their own data to make better decisions across supply chains, streamline product development and improve manufacturing efficiency.

“Businesses today are confronted with challenges ranging from supply chain disruptions and labor shortages to geopolitical uncertainties,” said Muhammad Alam, member of the Executive Board of SAP SE, SAP Product Engineering. “SAP recognizes the imperative for agility and intelligence, driving innovation with AI-powered solutions to streamline supply chain and manufacturing processes. Companies can enhance operational efficiency and improve supply chain resiliency while delighting customers with superior service, paving the way for sustained growth and market competitiveness.”

Accurate and relevant real-time information helps mitigate the impact that supply-chain disruptions have on suppliers, manufacturers and distributors worldwide. SMA Solar Technology AG and other customers have already witnessed the benefits of SAP’s solutions, including an approximately 15% increase in supply chain workforce productivity, a 10% decrease in overall supply chain planning costs and a 10% reduction in inventory carrying costs and stock turnover rate.

“SMA Solar modernizes its manufacturing execution systems to support sustainable, risk-resilient manufacturing operations with the power of AI-enabled visual inspection in the SAP Digital Manufacturing solution,” said Heiko Kehm, SMA Solar head of IT Order to Cash.

Sixty-three percent of supply chain executives and 52% of operations executives have an AI strategy linked to business objectives, according to “The Importance of AI in Supply Chain and Operations,” a global 2024 IDC InfoBrief sponsored by SAP*. Fifty-one percent of the 2,000 survey respondents are embedding AI into supply chain planning business processes and key applications for real-time decision-making. Another 58% are using AI to increase operational efficiency and employee productivity.

Key improvements to SAP’s supply chain solutions to support customers’ AI-centric strategy include:

-

Optimizing decisions across the supply chain with AI-driven insights: Companies can now leverage higher volumes of machine data and integrate AI-driven visual inspection by computer into their production processes, enabling a remarkable increase in quality through automation.

-

Streamlining product development: Product developers can now use SAP’s AI copilot Joule to gather and enhance new product ideas quickly and effectively using natural language queries. Joule also helps tag product designs with business data, so they visually contextualize business-critical information.

-

Detecting equipment anomalies: Using AI, asset operators can proactively address potential breakdowns based on sensor data collected from smart devices and edge gateways. This new capacity utilizes the cutting-edge Cumulocity IoT platform from Software AG, which is planned to be embedded in the SAP Asset Performance Management application in Q3.

-

Improving field response: Customers can optimize driving routes and allocate job assignments efficiently with integrated real-time traffic data and machine-learning-trained models, which enable the right field service technicians to reach their destinations on time.